Glorious GMMK Pro review

The Glorious GMMK Pro is easily the most controversial release in the custom mechanical keyboard scene as of mid-2021. It proposes a $170 option that checks off many of the boxes enthusiasts seek, namely a gasket-mount design and a CNC aluminum case (with a rotary encoder sprinkled on top). However, Glorious is a brand that has had a fairly murky history in the mechanical keyboard community. I spent two months with a GMMK Pro I purchased myself to find out if it’s simply an exercise in marketing buzzwords or if it actually delivers a viable option at an affordable price point.

Specs

Form factor – 75% (82 keys, exploded layout)

Construction – gasket-mount

Case – CNC aluminum with anodized finish

PCB – hotswap (south-facing, 5-pin, per-key RGB), USB-C via daughterboard, “VIA/QMK support” (still not fully supported)

Plate – aluminum (included); polycarbonate, brass (purchased separately)

Stabilizers – screw-in (Glorious-branded ones included)

Pricing – $170 (reservation link)

Availability – flex batches / eventually in-stock

Disclaimer – I purchased the GMMK Pro with my own money. I have no financial arrangement with Glorious, and all opinions are my own. A major thank you goes to my friend Sanjeev for lending me his GMK sets to use in the photos.

Introduction

In order to provide some context into the state of the keyboard hobby when the GMMK Pro was introduced, allow me to set the stage.

It’s the morning of November 1st, 2020. CannonKeys (a well-established vendor) is opening the limited group-buy for the Satisfaction75 R2, a desirable 75% custom keyboard with a rotary encoder (knob) and a tiny OLED screen. It sells out in mere minutes despite its substantial $480 base price tag and the sizable run of 1200+ units. Custom keyboard enthusiasts everywhere are distraught and a few even send threats to the owner of CannonKeys (imagine if these same people were to discover the Nike SNKRS app).

A few days later, on November 4th, Glorious enters the scene by announcing the GMMK Pro. It adopts a similar exploded 75% layout as the Satisfaction75 and also features a knob. The spec sheet also checks off many commonly sought-after features in the keyboard community – gasket-mount, rotary encoder, CNC aluminum case, screw-in stabilizers, 5-pin south-facing hotswap, centered USB-C, QMK/VIA compatibility, RGB backlighting, and side accent lighting. The real kicker? Glorious prices it at $170 and promises to continuously restock the board. Hype and discussion are at an all-time high about this new contender.

Pre-orders began on November 11th – the process involved putting down a $70 refundable deposit and waiting for the boards to be ready to pay the other $100. When one batch sold out, the ship date would simply be pushed back instead of being completely out-of-stock. I joined the first batch at launch, getting my email to complete my purchase at the end of March and receiving my GMMK Pro about a week into April.

The overall response to the GMMK Pro around the time of the announcement was overwhelmingly positive, but as time went on, the community grew a bit skeptical of Glorious’s ability to deliver all that was promised. Let me explain – Glorious is a company that has had a rocky relationship with the mechanical keyboard community. Despite their experience in making affordable versions of popular PC peripherals, their approach has raised eyebrows in the past (a Google query for “Glorious Holy Panda controversy” will reveal the full backstory, but the tl;dr is that Glorious made a replica of a popular community-created switch and copyrighted the name in the process).

The GMMK Pro comes in your typical gamer-brand packaging – the keyboard is well protected by a sheet of foam, but the design is nothing to write home about. Under the keyboard is a braided USB-C cable, a keycap puller, switch puller, some extra gasket foam strips, and a Glorious sticker. The keycap puller and switch puller are pretty much unusable, but the USB-C cable is actually quite decent. It’s a thin braided cable similar to those attached to gaming mice, which I prefer to some of the rubberized coiled cables included with budget custom keyboards.

Extras such as the polycarbonate plate are separately packaged in branded boxes as well. The really strange decision here was to fit a padded manila envelope inside of the fully branded retail packaging. This does effectively protect the bendy plate, but it feels incredibly strange nonetheless. It also comes with its own set of 14 screws taped to the manila envelope.

Oh, and for those new to the custom keyboard world, you will need to bring your own set of keycaps and switches (82 switches to be precise) to complete the GMMK Pro build. Custom keyboards are typically sold without these components to allow users to build to their preferences, both visually and in terms of feel.

Design and Construction

The GMMK Pro comes mostly assembled for a kit, so you could theoretically just insert switches and put keycaps on to get going. However, I’m going to go through the way the keyboard is put together to better understand why it sounds and feels the way it does – as well as to prepare you for what you’ll go through to modify things like stabilizers and swap builds.

The top case is secured via eight Phillips screws that go into the bottom case (four along the top edge, four along the bottom edge). To release the top case, you will also need to remove the knob. Underneath, you’ll find the plate/PCB assembly sitting on some foam strips along the outer edges of the bottom case (five foam strips along the top edge, five along the bottom edge, one on each of the left and right sides). Tabs protrude from the plate to allow the assembly to rest on these foam strips. Once you unplug the JST connector from the underside of the PCB, you can release the plate/PCB assembly. Underneath the PCB, you’ll find a 2.5mm sheet of foam and a cable routing channel in the bottom case. This leads to the daughterboard for the centered USB-C port. This is a nice touch that even some higher-end keyboards do not have. Oddly, the daughterboard is secured via only one screw in the center rather than four around the corners. The bottom case also features alignment pegs, which facilitate assembly of the board by securing the position of the PCB/plate assembly. On the underside of the bottom case are four cylindrical rubberized feet in the corners, which do a decent job of keeping the keyboard in place.

To separate the plate from the PCB, you will need to undo a whopping twelve Phillips screws – four along the top edge, four along the bottom edge, two along the left edge, two along the right edge, and two standoffs in the center of the PCB. The four mounting points on either side also do double duty to secure the diffusion panels for side lighting. The plastic diffusion panels are translucent with a cloud shape and a piece of white cardstock glued on top to prevent bleed into the keycap area. Integrated into the walls of the top case is a flat second layer of diffusion. Between the plate and PCB is an optional 3.3mm layer of foam that is lightly taped to the plate at one spot. The number of mounting points makes sense given that Glorious probably expects most buyers to just use the keyboard as-is. From an enthusiast’s perspective, the construction is probably a little unnecessarily complex, especially in order to do things like modifying the stabilizers.

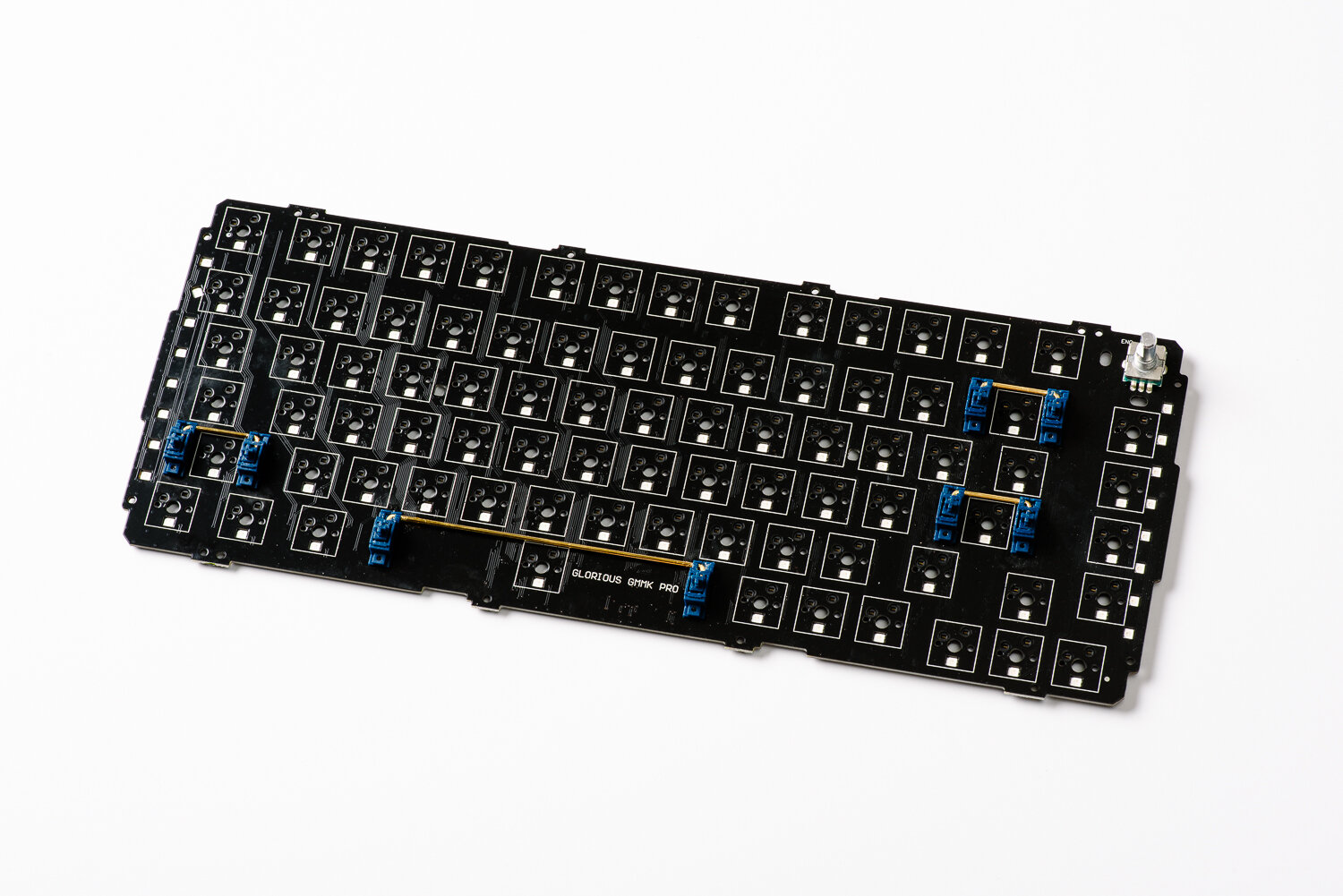

The gloss black PCB features hotswap sockets that support 5-pin switches in the correct south-facing orientation. There is also per-key RGB via SMD LEDs. There are eight SMD LEDs on the far left and right that light up the two layers of diffusion panels for accent lighting on the sides of the case. The hotswap sockets are Glorious branded, but they do not seem to offer any notable advantages over the typical Kailh sockets. My personal recommendation with hotswap boards is to completely disassemble the board and put your finger on the backside of each socket when installing switches. Although this may seem like a hassle, I strongly believe the time spent disassembling the board greatly outweighs the risk of ripping these sockets off during installation. The microcontroller used is an STM32F303 for those who might be familiar.

The metal plate options are punched rather than CNC machined. In theory, this means that the tolerances for the cutouts may not be as precise. In practice, I didn’t really experience any issues with getting a good fit with the switches. However, there is a widely reported issue of the stabilizer cutouts being too small for the Durock stabilizers that are found everywhere. The plates also have folded-over areas that give the plate some depth and areas to take the PCB screws.

The polycarbonate plate is injection molded and features additional alignment tabs with the PCB. Technically, if you take everything apart when you swap switches (which you should), you don’t actually need to use any screws to secure the plate and PCB together (the switches will hold everything in place without any problems).

I won’t beat around the bush – I simply do not recommend using the included stabilizers because they will sour your first impression of typing on the GMMK Pro (the spacebar stabilizer rattle is particularly egregious). As someone who generally tries to be frugal when possible, I wondered if I could remedy the stab performance by applying some lube to the existing ones instead of replacing them with more expensive aftermarket ones (relubing stock stabs worked really well on my KBD67 Lite). Do NOT be like me. I repeat, do NOT waste your time trying to modify the stock GMMK Pro stabs. The application of factory lube is absolutely atrocious – the whole stabilizer assembly is doused in lube, the entire wire and the outsides of the stabilizer housings included. After painstakingly wiping these down and applying Krytox 205g0 in the usual areas, the stabilizers are still completely offensive. Being aware of the incompatibility with Durock stabilizers, I went with some C3 ones I had on hand to avoid a headache. These made for a tremendous improvement, especially with the spacebar that you’ll hit every other second when typing.

The GMMK Pro measures 20mm tall in the front (including 2mm added by the feet), 34mm tall in the back, 332mm wide, and 136mm deep. The typing angle is 6 degrees. Fully assembled, the GMMK Pro weighs around 3 lbs, 9.5 oz. I think this weight is a big part of why the keyboard will make a great impression on first-time custom keyboard owners. Having been able to put together a small handful of custom keyboards (as heavy as 7+ lbs), I think the novelty of a very heavy keyboard has worn off on me a bit. That said, I think the 3-4 lbs assembled range is a decent weight for a 65-75% keyboard that you don’t plan to transport often.

Aesthetics and Details

The GMMK Pro has a fairly clean and angular design that can be broken down into two visual components – a flattened rectangular prism and a flattened triangular wedge that it sits on. The biggest defining characteristics of the keyboard are the rotary encoder, exploded 75% layout, and diffused LED side lighting. I think the keyboard is completely inoffensive in its look – apart from the side lighting. You can turn the lighting off if you want your keyboard to look less like a gaming peripheral, but then it leaves two translucent plastic strips along the sides.

The GMMK Pro is available in White Ice and Black Slate. White Ice is essentially a silver color. I opted for the safer Black Slate option during the pre-order because I feel that silver finishes can look cheap depending on the surface texture. Up close and in-person, the black anodization has a bit more sheen than other treatments I’ve seen, coming off as slightly more metallic than matte due to the texture.

Looking at the face of the keyboard, the top bezel comes off as significantly smaller than the bottom bezel. This is because the thickness of the top bezel is matched to the bezel below the arrow cluster (both are 5.85mm) rather than the bezel below the spacebar (9.9mm). The right bezel and left bezel are matched at 9mm each. Personally, I feel that the proportions would look nicer if the top bezel were larger and at least matched the thicker portion of bottom bezel. The gap between the keycaps and bezel also strikes me as a bit large, exposing a sliver of the sides of the switches even when using true Cherry-profile keycaps from GMK.

Due to the relatively small radii of the corners and the minimal filleting of the top edges, the keyboard has a relatively boxy look. The bottom-facing edges are on the rougher side, but these are not really visible – nor are they overly sharp when moving the keyboard around. The back side of the keyboard is a bit less refined looking due to the cylindrical recesses machined out to accommodate for the screwdriver shaft during assembly. The USB cutout is centered and has a recessed surround. Although the port itself is not recessed, the surround is deep enough, and the top ledge covers enough of the cable that you will never see the metal portion of the connector.

The knob has knurled sides and chamfered top edges. It sits nicely in the recessed area in the top right corner of the keyboard. The inner portion of the knob is made of plastic and fits onto the rotary encoder via friction (rather than screws).

The aluminum plate has a black anodized surface, whereas the polycarbonate plate has a textured backside and a smooth matte face. Backlighting is not very bright with the aluminum plate, although it distributes a bit more nicely with the translucent polycarbonate plate. However, when using the polycarbonate plate, the side accent lighting bleeds significantly into the backlighting area on the left and right edges (despite the cardstock on the diffusion panel). This means that you won’t be able to cleanly enable side lighting without also having backlighting on. The walls of the top case are a bit thin around the plastic diffusion panels, which makes the top case feel slightly less sturdy when lifting the keyboard.

The underside of the GMMK Pro features an absolutely massive Glorious logo debossed into the aluminum, as well as an FCC regulation sticker in a recessed slot. Frankly, the sheer size of the logo is a bit distasteful – even for a gaming peripheral (it reminds me of a giant Hershey’s chocolate bar). With that said, I’m glad that there is no visible branding on the top side of the keyboard which would be visible during use.

Overall, the look of the GMMK Pro is inoffensive, especially at this price point. It is not a particularly sophisticated-looking keyboard, but its visual shortcomings are also fairly easy to ignore in actual use.

Build Quality

My biggest issue with the build quality of the GMMK Pro is the fact that the polycarbonate plate is simply not manufactured correctly. When you combine it with the PCB and insert switches, the entire assembly bows upwards in a U shape. You can visibly see the assembly rock up and down if you push down on either side once it’s sitting in the bottom case. Once the top case goes on and forces the assembly flat, this isn’t as noticeable but I do wonder if this will impact the longevity of the PCB. Long story short, it doesn’t fit as it’s supposed to.

The other major gripe I have is the durability of the Phillips screws included; they simply feel very thin and like they might strip if you stare at them the wrong way. With something marketed to enthusiasts who will be frequently tinkering with the parts, more rugged-feeling screws (preferably with hex or Torx heads) would have been a much better fit. The threads on one of my exterior case screws stripped despite being pretty careful on disassembly and assembly. This sort of design decision can really only boil down to cost-cutting and a lack of experience in creating products for enthusiasts.

The anodization job on the aluminum is relatively even all around. The surface texture is a bit coarser than on other keyboards I’ve tried but is not really an issue. The back side of the bottom case is the only area where some machining marks are visible on the surface. Time will tell if the anodization job is durable enough, although I see a bit of the finish wearing away around recesses for the screws.

As mentioned earlier in the design section, there are some issues with the cutouts on the punched plate when fitting certain popular stabilizers. On the other hand, the switch cutouts were reasonably tight in the aluminum plate. With the polycarbonate plate, they are quite a bit looser – to the point that you can basically push them out from behind without grabbing the switch tabs. When swapping keycaps, the switches will are very likely to come out with the keycap when using the polycarbonate plate.

On underside of the PCB, the soldering job behind the encoder is not the cleanest; functionally speaking, this doesn’t really raise any concerns thankfully.

My last minor complaint with the build quality of the GMMK Pro is that the walls of the top case feel pretty thin. I measure the left and right sides to be about 1.25mm thick. This, combined with the cutout for the side lighting, doesn’t inspire a ton of confidence in the structure of these top walls.

Typing Sound

The GMMK Pro comes with an aluminum plate by default. You can also add polycarbonate or brass plates at checkout. I ordered a polycarbonate plate alongside the keyboard to see how much it would affect the typing sound and feel.

If you want the SparkNotes version of the sound portion of the review, I would say that the GMMK Pro is an okay-sounding keyboard. Why is it just okay? To my ears, the GMMK Pro sounds simultaneously muted and a bit hollow (as contradictory as these descriptors sound). The overall sound signature is on the deeper end, but I don’t get the sensation that each keystroke is precisely punctuated. Despite it being packed full of foam, the keyboard doesn’t have a dense sound to it. The alphas are relatively consistent sounding, with a noticeably deeper number row and F row. I definitely wouldn’t go as far as to say it’s a bad-sounding keyboard, and it doesn’t have any inherently offensive sound qualities like ping when using properly lubed switches. However, if a random friend asked to hear “keyboard ASMR,” this is not the first keyboard that I would grab. And you know what? This opinion doesn’t come from a place of elitism either. My KBD67 Lite, a $109 plastic keyboard, actually has a more pleasant sound signature to my ears.

Naturally, I wondered what the GMMK Pro would sound like if I removed the plate foam or bottom foam. So I proceeded to build and rebuild the GMMK Pro a little over half a dozen times to try different combinations – with both pieces of foam, with plate foam but no bottom foam, with bottom foam but no plate foam, no foam at all, with a polycarbonate plate, and so on.

With both foam pieces installed, the keyboard actually still sounds pretty resonant. The sound is slightly on the deeper end, but I was surprised at how loud the keyboard was despite the integration of so much foam. With just the plate foam and no bottom case foam, the sound of the keyboard was slightly less “full.” With both pieces of foam removed, the sound of the keyboard became a bit tinny and “loose” for the lack of a better word. It wasn’t significantly hollower sounding, but it did seem a bit higher pitched. With the plate foam now removed but with the case foam put back in, it actually sounded a bit louder than with no foam at all. Having the bottom piece of foam definitely helps to make the keyboard sound noticeably “fuller” (which is consistent with earlier findings when the bottom foam was removed). On the other hand, the inclusion of plate foam definitely reduces the volume a bit and contributes to more of a muted sound. Switching over to the polycarbonate plate gave the keyboard a bit of a lower-pitched sound that I ultimately preferred.

If you want to tweak the sound of your GMMK with what’s included, I would recommend experimenting a bit with these foam pieces as I did. A good place to start is with both pieces of foam installed. If you want to open up the sound of the keyboard a bit, you can try removing the plate foam (it reduces the overall volume a bit). Beyond this, I would keep the bottom foam installed; the GMMK Pro just sounds a little lifeless and tinny without this piece.

Even with these recommendations, my biggest takeaway here is that not all foam is created equal. It seems that the foam used in the GMMK Pro is a bit more porous than the dense Poron used in other modern boards. The KBD67 Lite actually uses an even denser silicone between the plate and the PCB. The foam in the GMMK Pro is slightly effective in muting the sound signature but really does not do a whole lot to tighten up the sound. That’s why there’s still a hint of hollowness with each keystroke, and each stroke doesn’t sound as deliberate as with something like the KBD67 Lite.

Oh, and we’ve already talked about the included stabilizers earlier in the review. Just don’t bother trying to use or modify them. Pony up the additional $20 or so for some quality ones to avoid completely souring your first impression of the GMMK Pro.

Typing Feel

Now let’s talk a bit about typing feel – the GMMK Pro is a fairly firm keyboard, despite the gasket-mount design with strips all around the perimeter.

The primary culprit here is that the gaskets are simply not thick or cushion-y enough to allow the PCB/plate assembly to push down into the gasket strips. There is so much compression that the mounting style might as well be rigid. Switching to the polycarbonate plate does help to make the bottom out a little less fatiguing, but there is no chance of flex as some may associate with gaskets. The bottom foam does also have a bit of compression into the hotswap sockets of the PCB, which some may see as a contributor to a firm typing experience. However, even with the bottom foam removed, there simply isn’t much room in the bottom case below the PCB to allow for flex, even with the bottom foam removed. If you set the bare PCB on the gaskets along the edge, the hotswap sockets bottom out almost immediately on the bottom case.

Although the polycarbonate plate is very bendy as a standalone piece, I’m inclined to believe that any reported flex here can purely be attributed to placebo effect. Whether or not you include the plate foam, there doesn’t seem to be much potential for flex between the plate and PCB once all the switches are mounted. Changing to a polycarbonate plate will in fact yield a different bottom-out feel but not introduce any actual bounciness one might think that they feel. I removed all standoffs and screws when putting the plate/PCB assembly together as well to eliminate any additional factors of stiffness (you can rely purely on the switches to hold the assembly together if you take everything apart).

Will these notes on typing sound and feel matter a lot to most first-time buyers of a custom mechanical keyboard? Probably not. However, I think it’s still important to include these enthusiast perspectives because pleasant typing sound and feel are not constrained by price. I have not sampled an extensive amount of keyboard setups by any means but do feel that I am starting to develop some preferences a couple of custom builds in.

Layout and Programmability

To expand a bit more on preferences, I am not the largest proponent of 75% keyboards. My favorite layout at the moment is 60%, closely followed by TKL (60% is the most compact layout that doesn’t feel inconvenient to me, and it ensures that I don’t have to move my hands away from the home row much when typing. TKL, on the other hand, has very classic proportions and is nicely spaced out, so I’m never hitting the wrong keys)

That said, I personally feel that the exploded 75% implementation in the GMMK Pro is as nice as a 75% layout gets. The blockers between the main alpha cluster, F row, arrow keys, and far right mod column help to visually break up the face of the keyboard. Practically speaking, this separation also makes it easier to reach for each of these clusters while touch typing (you can feel for the edges of the clusters to confirm you’re hitting the right keys). The inclusion of F13 seems to be a popular choice among enthusiasts; as someone who doesn’t really use the F keys, I don’t have too many thoughts on the matter. It is worth noting that although 75% keyboards are not my personal preference, the layout is very easy for laptop/full-size keyboard users to familiarize themselves with. Newcomers will want to make sure that the keycap sets they buy include a 1.75U right shift key to work with the GMMK Pro.

Programmability is another big point of contention with the GMMK Pro. When the keyboard was announced, Glorious promised that it would be QMK and VIA compatible (two standard pieces of key remapping software in the custom world). When the first boards shipped, owners found out that the keyboards were in fact not compatible with VIA. Instead, you had to download Glorious’s proprietary Core software to push a mandatory “day 1” firmware update and use that to configure the board. At the time of writing, Glorious is adding additional functionality to the QMk support but there is still no official VIA support.

This would probably be a bit more acceptable if Glorious’ Core software worked well, but it is really not a very intuitive piece of software on any level. Remapping keys requires scrolling through a list, the UI in the configurator doesn’t update the keys you change, and you have to hit save after every single key edit. The implementation of layers is limited and confusing as well. I’m really not trying to bag on Glorious here, but I think that many users will miss out on programmability (potentially one of the big advantages of a custom keyboard) altogether because they do not want to figure out the software. It seems that the team who wrote the software placed more emphasis on building in RGB effects than proper programmability (but even this menu is not very clearly laid out).

The lack of a Mac version of the Glorious software also makes the delay of VIA support a bit more troublesome as well. This is somewhat understandable for a company named Glorious PC Gaming Race, but it’s still a bummer to not have a visual configurator if you use a Mac. To add insult to injury, the global semiconductor shortage means that future GMMK Pros (after Q3 2021) may have to resort to a different chip that doesn’t support QMK easily.

Features

I wanted to take a second to address the inclusion of a rotary encoder in the GMMK Pro as well. When the keyboard was announced, there seemed to be a lot of interest in this feature. It was a defining characteristic of the Satisfaction75, and many have been drawn to this gimmick/feature since.

In theory, having a knob on a keyboard is pretty cool. It feels like a more analog way to control and fine-tune settings like volume. In practice, I really did not find a knob to be more practical than clicking two keys to go up and down. For one thing, your thumb bumps against the backspace and top right modifier key when reaching for the knob. For another, the notches on the knob are a little too easy to just scroll past. I’d rather the notches feel way more solid (like a shutter speed dial on a camera) or be completely smooth and dampened (like the focusing ring on a camera). The implementation on the GMMK Pro knob is a weird in-between, and it doesn’t really inspire confidence. That said, I didn’t notice too much wobble with the knob, and clicking on it (to mute) actually feels pretty solid. I’m just not convinced that having a knob on a keyboard is all it’s cracked up to be.

The other nice “feature” of the GMMK Pro is its 2-year warranty. Most keyboards in the custom scene do not have an official warranty period, and a lot of the customer support is done out of goodwill. It’s nice to know that there is a semi-large company standing behind the product with the resources to issue replacements in case anything happens.

Competition

Under $200, there are not a whole lot of custom keyboards that feature a CNC aluminum construction. The majority of the commonly recommended options in the $100-150 price point are manufactured from injection-molded plastic. There isn’t anything inherently wrong with plastic (some would say it’s actually an acquired taste in terms of acoustics). However, there is also something inexplicably satisfying about picking up a hefty keyboard constructed from metal for the first time.

The two leading options that are made of metal would be the Idobao ID80V2 ($199) and NovelKeys NK65 v2 Aluminum ($185). The ID80 features an integrated plate design, which will yield a less configurable (and more rigid) sound and feel than the GMMK Pro’s mounting system. I had positive impressions of the NK65 v2 Aluminum when I purchased one a little over half a year ago, but the keyboard scene has evolved a bit since then. The NK65 v2 is a 65% keyboard rather than a 75%, but both are very friendly layouts to learn. It also features a mounting system that combines tray mount and top-mount, so the typing experience is very firm (and there is no option to change out the plate material from aluminum). If you must have metal, the GMMK Pro is hard to look past in mid-2021.

If sound and feel are paramount to you, I would recommend taking a look at the injection-molded plastic options such as the KBDfans KBD67 Lite ($109 group buy, $129 in-stock), Wuque Studio Ikki68 Aurora ($129 group buy), TKC Portico ($119 group buy, $135 in-stock), and RAMA KARA ($160 group buy). Out of these, I have personally tried the KBD67 Lite (and have an unbuilt Portico on hand). The KBD67 Lite has a thockier and poppier sound signature than the GMMK Pro, as well as a softer typing experience. I personally find that I’m reaching for the KBD67 Lite over the GMMK Pro more often when I want to type for extended periods of time.

For those who are a bit more adventurous, there is actually another contender apart from the CNC aluminum and injection-molded plastic options – the CannonKeys Bakeneko60 ($130). The Bakeneko60 utilizes an open-source 60% design based on the legendary TGR x Singa Unikorn (and its gummy o-ring gasket mount). The drawback in terms of case construction is that it is die-cast instead of CNC machined and that it is painted rather than anodized. However, initial reviews have reported that the typing experience is very pleasant. This type of design may play a critical role in the budget custom space, trading off finishing quality to include both metal and an enjoyable typing experience in an affordable package.

Final Thoughts

I sat on this review for quite a while before deciding to publish it (a full two months after I received my GMMK Pro). On one hand, it felt weird to gripe about all the things I wasn’t thrilled about for fear of sounding elitist and bandwagoning on the Glorious hate train. On the other hand, it also felt weird to endorse it purely due to the lack of other viable budget options constructed of metal.

Controversy in the community and manufacturing oddities aside, the GMMK Pro is a fairly decent option for a beginner looking to get into the world of mechanical keyboards. It feels premium enough and has enough configurability to serve as a great introduction (or even be the end-all and be-all for those who don’t want to dive deeper).

I have to note that, as an enthusiast, the typing experience unremarkable but also fairly inoffensive. There are better sounding and feeling keyboards (some of which are actually a bit cheaper than the GMMK Pro), but these are often made of plastic. At the end of the day, as a first-time buyer, you will either be very satisfied with the GMMK Pro and not be curious to explore any further, or it will whet your appetite enough to push you down the rabbit hole.

If you do decide to buy the GMMK Pro, make sure to budget an extra $20 for stabs/lube and another $20 for the polycarbonate plate to significantly take the experience up a notch.

In terms of what I would like to see Glorious improve, the biggest items would be to fix the warped polycarbonate plate design, include more durable screws, and get VIA support working as promised. It would also be nice to see a V2 of the GMMK Pro with an improved mounting system for a better typing feel and acoustics.